0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

Suzhou Zhiguan Yisheng Information Technology Co., Ltd. has been committed to the Internet of Things since its inceptionRFIDResearch and implementation of industry application technology. For years of service1000+Home to all types of customers.

The diversified demand for warehouse management will usher inWarehouse managementRe-optimization and definition, more and more new technologies will be applied to all aspects of storage production. Operations such as warehouse arrival inspection, warehousing, warehousing, distribution, shifting, inventory and inventory will require accurate data collection.RFIDInformation automation data collection has become an important helper of warehouse management,RFIDWith the rapid development of technology, the era of warehouse automation, digitalization and real-time management has arrived.RFIDWarehouse management system It is important to reduce the operating cost of warehouse management.

Warehouse data must be supplied byWarehouse managementStaff manual input data, warehouse management operations not only a large workload, but also seriously affect work efficiency, and even many warehouse data can not update the system in time, but also can not understand the distribution of materials in the warehouse and warehouse storage capacity, workers in the placement and collection of materials, there is no scientific system guidance, there may be material location error or material collection error or loss phenomenon.

RFIDWarehouse management systemAs a new generation of automatic identification technology, it has the characteristics of high security, fast reading speed, strong penetration and large storage space. In the process of cargo storage, implement the stacking correlation of the received pallets one by one to ensure the real-time and physical consistency of the stacking correlation; Scan the entire pallet for arriving smoke to improve warehouse scanning efficiency. At the same time, the logistics tracking of finished pallets based on stacking is established to improve operational efficiency, which is closely combined with the three cleaning work from code to project to improve the sorting and collection efficiency of commercial enterprises.

RFIDThe warehouse management system automatically collects the data of warehouse warehousing, warehousing, warehousing, inventory and other operational links, so that the data of each link of warehouse management is fast and accurate, and provides a strong guarantee for timely and accurate grasp of warehouse management data.RFIDWarehouse access management makes the warehouse more efficient.

In the actual warehouse management link, the work is generally carried out from the three dimensions of warehousing, management and warehousing to improve the accuracy of warehouse management and upgrade the warehouse management service:

1. Warehousing of goods Through warehouse entranceRFIDAutomatic sensing collection reading device to identify itemsRFIDtag (Electronic tag)The information of the corresponding project is found in the database and automatically entered into the management system. The system records the stored information and verifies it. If there is an error, prompt error information, send an alarm signal, and automatically prohibit storage.

2. Inventory management Traditional warehouse inspection, management and monitoring of goods after storage often consume a lot of labor, it is difficult to ensure the accuracy of information. Through the identification system, regular inspection of classified goods, analysis of changes in commodity inventory, and timely data display on the warehouse platform. When the goods are displaced, throughRFIDThe identification system automatically collects goods RFIDtag (Electronic tag)Find the corresponding information in the database, and automatically enter the information into the warehouse management system, record the name, quantity, location and other information, check whether there is an abnormal situation, abnormal instant alarm, to ensure the safety of warehouse goods.

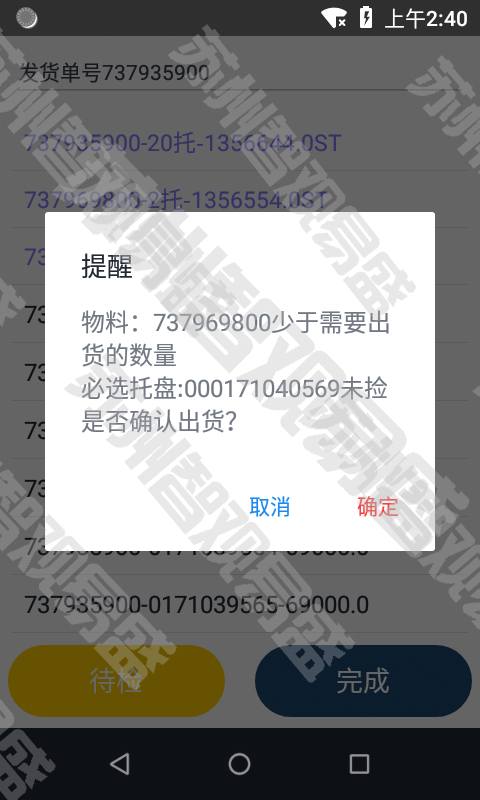

3. Commodity delivery In the goods delivery link, with the goods delivery order requirementsRFIDtag (Electronic tag)Identify, scan cargo and locationRFIDtag (Electronic tag)Confirm outgoing items and update inventory. When the goods arrive at the exit channel, the identification system will automatically readRFIDtag (Electronic tag)And retrieve the corresponding information in the database. Compared to the order information bank, if correct, the inventory of goods can be reduced accordingly; If an exception occurs, a prompt message is stored in the management system, facilitating immediate security monitoring and troubleshooting.

Why did the introduction of a costly fixed asset system end in failure? No matchingRFIDEquipment, too time is not clear, but can not count the assets that are out of reach, asset managers do it and give up. Why buy and useRFIDEquipment, still can not achieve quick inventory operation? Different application scenarios for labels, collection equipment selection are very sophisticated, yesRFIDLack of understanding of the features, inaccurate matching, instead.....

The view of wisdom is easyRFIDWarehouse management system products or raw materials have a clear identity binding, which can effectively improve the efficiency and accuracy of sorting and shipping Remote data reading without manual inventory, improve inventory turnover and warehouse utilization.

According to the statistics of the National Archives Administration, by2008The national archives warehouse area is285.610,000 square meters, and the archives are25284.5manmaki;There are also all kinds of audio and video files, electronic files based on disk discs, microfilm files, etc. And every year, the archives warehouse also undertakes a large number of archives into the library storage tasks, most of the archives warehouse is close to saturation...